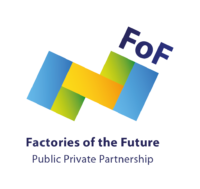

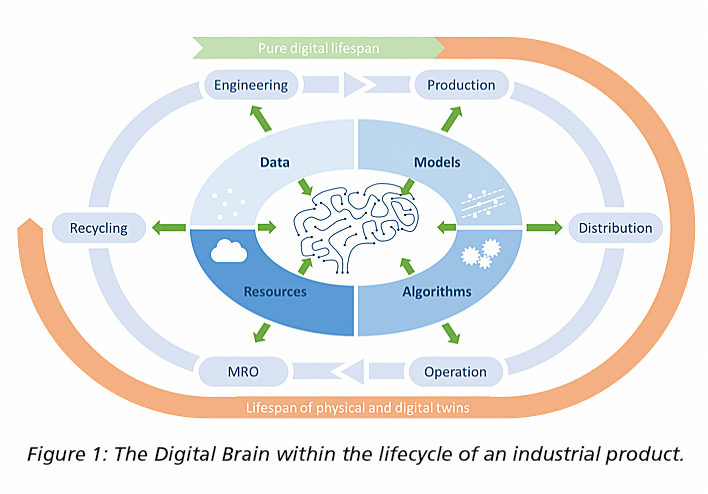

The DIGITbrain Project, which has started on 1st July 2020, will heavily build on the results of the CloudiFacturing project. The Digital Brain is a novel concept, extending the Digital Twin towards supporting the full lifecycle of industrial products and facilitating the configuration and orchestration of assets related to an industrial-product instance.

The manufacturing industry is in constant evolution; customers have new requirements and want more personalisation; interoperability with new products and technologies is expected; legislations, regulations, and norms are becoming stricter. All these aspects cause an increasing pressure that the manufacturing industry needs to master in the most efficient and innovative way possible. Especially manufacturing small and medium-sized enterprises (SMEs) are challenged by these aspects, because of the limited resources and the difficulty in accessing digital technologies and advanced manufacturing hardware tailored to their needs.

Compared to the digital twin concept which is more and more used by manufacturing companies today, the DIGITbrain concept will go one step further by developing the 'Digital Product Brain' which will store data about production lines and machinery throughout their entire life cycle. By collecting this data machines and production assets can be customised and set-up for very specific manufacturing tasks. This will enable a new Manufacturing modell, called Manufacturing as a Service, which will allow for the creation of much more specialized products, also in smaller quantities, but still in an economically profitable way.

The DIGITbrain Project, which has started on 1st July 2020 and is composed by a consortium of 36 partners coordinated by PNO Consultants. During its lifetime it will attract further 35-40 collaborators in two Open Calls, mainly technology and manufacturing SMEs.

The DIGITbrain Project, which has started on 1st July 2020 and is composed by a consortium of 36 partners coordinated by PNO Consultants. During its lifetime it will attract further 35-40 collaborators in two Open Calls, mainly technology and manufacturing SMEs.

It has the ambition to transform the CloudiFacturing (CFG) solution and ecosystem, which is being developed within the CloudiFacturing project towards the requirements of Manufacturing as a Service, utilising the Digital Brain and its underlying technology components. Over 20 highly innovative application experiments will illustrate how the Digital Brain and its lower level services can be utilised via the CloudiFacturing Digital Marketplace, in order to empower SMEs with MaaS. Using cloud / HPC-based modelling and simulation, CloudiFacturing aims to optimise production processes and producibility, leveraging online factory data and advanced data analytics (through the Platform and Digital Agora); thus, contributing to the competitiveness and resource efficiency of manufacturing SMEs and to the vision of Factories 4.0 and the circular economy. CloudiFacturing solution currently involves 14 industrial demonstrators in order to demonstrate its capabilities. Until the end of the project in April 2021 another seven application experiments will be implemented within the project.

CloudiFacturing Solution, incorporates two major components: the Digital Agora (or Digital Marketplace, the top layer), and the CloudiFacturing Platform (all other layers below this marketplace). The CloudiFacturing Platform is a meta-platform that can efficiently communicate with multiple workflow or application executors (e.g. SemWES Platform[1], CloudBroker Platform[2], or Flowbster[3]), in order to deploy and orchestrate engineering and manufacturing workflows and applications on cloud and HPC resources. The CloudiFacturing Digital Marketplace is the user-facing interface to the CloudiFacturing Solution, providing community-building functionalities, a marketplace for promoting and showcasing service.

Klick here for more information about the CloudiFacturing Digital Marketplace:

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).