EXPERIMENT DESCRIPTION

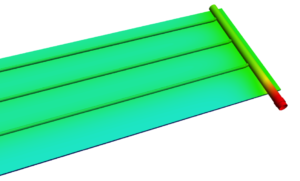

In this experiment, EndeF would like to optimize the lamination process in the manufacturing of hybrid solar panels. In this procedure, the adhesive between the photovoltaic module and the heat recovery unit is melted and cured through a thermal process in an oven, achieving the union of both components. The oven configuration (temperature ramp, air mass flow, and distribution) is critical in order to ensure proper thermal treatment of the adhesive along the whole panel, to avoid hot spots or to reduce the energy consumption. The optimal configuration of the oven depends on external variables, such as the ambient temperature, the thermal properties of the adhesive and the geometry of the solar panel.

The aim is to minimize the energy consumption and power needed by the oven, as well as minimizing the time required per panel and the number of them with manufacturing defects. EndeF will reduce the process time and the energy consumption of the lamination process as well as increase its production capacity. Adapting and porting a fluid flow and heat transfer simulation software package (based on Computational Fluid Dynamic techniques, CFD) to the Cloud to simulate and optimize the solar panels manufacturing, is what we are trying to achieve with this experiment.

TECHNICAL IMPACT

EndeF will reduce manufacturing time by 20% and save energy by 20% (short-term) and by 30% (medium-term) in the lamination process. They will be able to supply more solar panels to their customers in less time.

NablaDot will obtain technical expertise in the development of CFD tools in the Cloud for non-expert users. This will allow them to approach other companies that manufacture hybrid solar panes and new prospective customers in the glass and metallurgy industry.

ECONOMIC IMPACT

Photovoltaics is a rapidly growing market, as shown by the CAGR (Compound Annual Growth Rate) of photovoltaic plants, equal to 40% between 2010 and 2016. By implementing this new solution EndeF expects to increase panels production (10000 panels/years), in turnover (5 million euros) and in providing jobs (80 jobs); another positive impact will be low emissions per year (4.542 tCO2 emissions avoided/yearly).

The expected impact for Nabladot is to gain the experience that will allow it to approach potential customers related to the rolling sector, show them new skills, hoping that they will assume the development of an ad-hoc tool for their specific process. Having sufficient experience, a turnkey tool of this type could be offered by around € 50,000. New customers mean new revenue and significant market penetration. In terms of expected impact, NablaDot hypothesizes one project per year in the short/medium term and more projects per year in the long term. This extra revenue would help NablaDot to settle and widen its income sources, becoming less vulnerable to changes in the core market (currently around 75% of income comes from the simulation of coal power plants). In turn, this would allow to hire more staff and expand to new markets.

EXPERIMENT 5 OUTCOME

Having a model in the cloud capable of predicting the performance of the oven to laminate a PVT system constitutes a huge advantage in this industry. The expected impacts of the implementation of the computational model as a cloud service in the production process of EndeF are a decrease by 8% of the energy consumption in the manufacturing of the panels, an increase of the manufacturing capacity per day, a decrease of the number of tests to set up the oven for a new panel, a reduction of the time and costs required to give an answer to the client, and avoiding hot spots in the lamination oven. As a result, the reduction of the manufacturing costs will allow EndeF to have a more competitive panel, expecting an increase in the sales by 10% thanks to the new production process.

Solar Panel Production

"The CloudiFacturing technology has allowed us to optimize the manufacturing process of our solar hybrid panels, with a reduction of time and costs that is reflected in the panel profitability. Highly recommended."

Isabel Guedea. Chief Executive Officer –EndeF Engineering.

CONTACT

Nabladot

Carlos Montañés

Zaragoza, Spain

carlos.montanes@nabladot.com

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).