Experiments Overview

In CloudiFacturing, minimum 21 cross-border application experiments will be conducted in three waves. Seven experiments comprising the first wave are already defined, while the participation in the second and third waves will be via Open Calls. All wave one experiments will run across national borders. All experiments bring together different expertise: technical knowledge from Cloud/HPC, data analytics, simulation, modelling, security, etc. and also business modelling expertise.

There are seven application experiments already finished from the First Wave. They have been followed by further seven new application experiments from the Second Wave. The process from the Third Wave has already started in spring 2019 with the Official Announcement of the Second Open Call. The selection process for wave 3 experiments is completed and work in their implementation will start soon.

Wave 1

- Experiment 1: Optimizing design and production of electric drives

- Experiment 2: Cloud-based modelling for improving resin infusion process

- Experiment 3: Improving quality control and maintenance at manufacturing SMEs using big data analytics

- Experiment 4: Numerical modelling and simulation of heat treating processes

- Experiment 5: Optimizing solar panel production

- Experiment 6: Optimizing efficiency of truck components manufacturing processes by data analytics

- Experiment 7: Simulating and improving food packaging

Wave 2

- Experiment 8: FLOWCALOP - Flowforming process calibration via cloud optimisation

- Experiment 9: CAPSUle - Cloudification of image analysis for human measure collection for Personalised Safety protection clothing engineering and production

- Experiment 10: SHION - Smart Thermoplastic Injection

- Experiment 11: CloudEcho - Cloudified Analysis of Multi-sensorial Data for Optimised manufacturing

- Experiment 12: Update of CAE Models on Actual Manufactured Shapes

- Experiment 13: OSICS - Optimisation of the Production Process of Metal Structures using OSICE

- Experiment 14: Twin_in_Fog - Data Twin-based and Fog Computing Driven Proactive Control and Maintenance in Laser-based manufacturing

Wave 3

- Experiment 15: BioOpt: Enhanced production of biomass furnaces through a simulation-based digital twin

- Experiment 16: Digital twin for optimal encapsulation

- Experiment 17: Fermicloud: Fermentation production optimisation using cloud manufacturing techniques

- Experiment 18: 3DCPAM: Advanced clothing production by additive manufacturing 3D printing

- Experiment 19: Ergonocloud: Cloud-based ergonomic verification for quality management in manufacturing

- Experiment 20: Clarion: Machine health assessment via energy monitoring

- Experiment 21: Optimum: Injection process optimization of moulding machines

More information on the new experiments will follow soon!

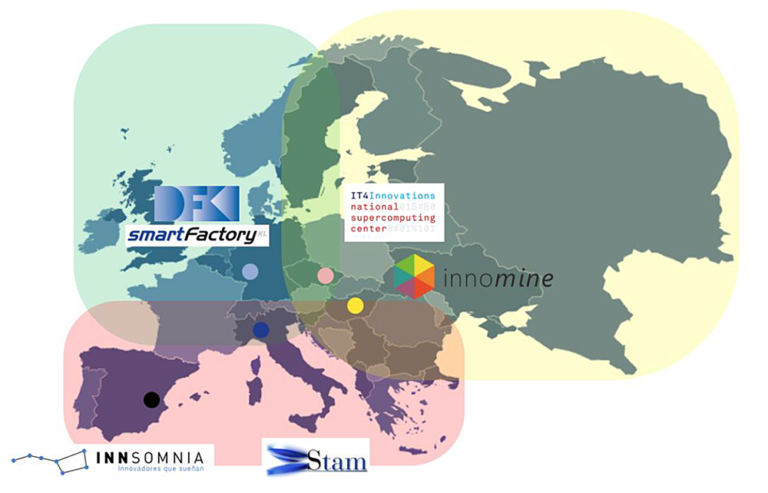

The following DIHs are partners in our project.

In order to maximise the impact of the experiments, each experiment is accompanied by a Digital Innovation Hub (DIH).

Have a look at the figure to see, which DIH is responsible for your area.

Innsomnia is a Spanish accelerator and incubator located in Valencia with +30 years of experience fostering innovation and improving access to finance for innovative firms, SMEs and start-ups in key sectors such as: Industry 4.0, Blockchain, Smart Data, Botadvisory, Predictive analytics, 5G, Robotics, Cloud, IoT, Artificial Intelligence, Fintech, Insurtech, Legaltech or Agriculture. Innsomnia supports Experiment 5 (Optimizing solar panel production).

Stam is an engineering firm specialised in the high-tech sector, providing turnkey solutions in the following sectors: automation & robotics, defence & security, aerospace, transports and energy. STAM has established partnerships with key players in the manufacturing industry: Faac, Kuka, CRF, OtoMelara, Comau and since 1997 is the technological provider of the European Space Agency. STAM supports Experiment 2 (Cloud-based modelling for improving resin infusion process).

Innomine Group is a leading innovation management and funding expert, with a solid track record in the field of innovation and international projects. Innomine focuses on international, highly complex Startup, scaleup, SME and corporate innovation projects and offers its communication, public funds and innovation expertise to best represent the interest of its clients. It is specialised in publicly financed innovation programmes, primarily in the high-tech sector and has a cross-disciplinary and cross-national team of professionally qualified consultants, with research and consultancy expertise in management, technology and European funding. Innomine supports Experiment 3 (Improving quality control and maintenance at manufacturing SMEs using big data analytics Partner) and Experiment 6 (Optimizing efficiency of truck components manufacturing processes by data analytics).

The German Research Center for Artificial Intelligence (DFKI) is the leading German research institute in the field of innovative software technology. In the international scientific community, DFKI ranks among the

most recognized "Centers of Excellence" and currently is the biggest research center worldwide in the area of Artificial Intelligence and its application in terms of number of employees and the volume of external funds. 485 employees from 60 countries are currently conducting research focusing on Smart Data & Knowledge Services, Cyber-Physical Systems, Multilingual Technologies, Plan-Based Robot Control, Educational

Technology Lab, Interactive Textiles, Robotics, Innovative Retail, Information Systems, Embedded Intelligence, Smart Service Engineering, Intelligent Analytics for Massive Data, Intelligent Networks, Agents and Simulated Reality, Augmented Vision, Language Technology, Intelligent User interfaces, and Innovative Factory Systems. Impact: more than 98 professorships of former DFKI employees, and 70 spin-off companies with approximately 2,500 highly qualified jobs. DFKI supports Experiment 1 (Optimizing design and production of electric drives) and Experiment 7 (Simulating and improving food packaging).

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).